Pipe coating is precision work

The coating must be designed to withstand the climatic challenges of the environment and the properties of the medium being transported. It must also protect the pipe during transport, storage, and installation. Our modern facilities and corresponding software systems are operated by qualified employees. Only the successful interaction of all factors guarantees high product quality.

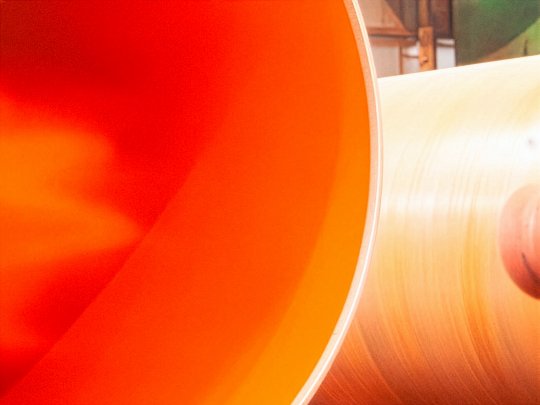

MÜLHEIM PIPECOATINGS offers a wide range of technically perfect and cost-efficient coating solutions. Standard solutions for external coatings are three-layer polyolefin coatings (PE/PP) and fusion-bonded epoxy coatings (FBE). The former was developed by Mannesmannröhren-Werke, one of EUROPIPE's predecessor companies. The standard solution for the internal coating of pipes is liquid epoxy coating.

Our coatings can be designed for operating temperatures of up to 120 °C. In addition, we can achieve a range of mechanical properties that withstand stress from tension, shear, or compressive forces as required.

Pipes for underwater installation are coated with an anti-slip coating, regardless of whether they are additionally coated with concrete. Polyolefin and FBE coatings with textured surfaces are applied or fine particles are mixed in, which make the coating more grippy with a so-called sandpaper effect. In addition to coating oil, gas, and hydrogen pipes, MPC also offers solutions for the long-distance transport of drinking water and wastewater. The internal coating used here is made of epoxy resin. The external coatings are identical to those used for oil, gas, and hydrogen pipes.

Unsere Beschichtungen erfüllen diese Anforderungen – und die Wünsche unserer Kunden.

Außenbeschichtung

Unsere Außenbeschichtungen aus 3-Lagen Polyolefinen oder Fusion Bonded Epoxy sind Korrosionsschutz und robuster mechanischer Schutz in einem System, abgestimmt auf Beanspruchung und Temperatur.